The Lean Methodology has been making positive inroads in the legal industry, and has so far transformed work processes by changing the pace and quality of legal work offered to clients. The Lean Methodology is not specific to law. It is a manufacturing technique adopted in the 1950s by Toyota, with the dual aim of increasing efficiency and building trust among clients by eliminating wastes and propelling a faster, more efficient, and robust manufacturing process.

This article highlights the lean methodology in detail and its subsequent manner of adoption in the legal industry.

For more information about the Lean Manufacturing process of Toyota, click here.

Check out our Legal Project Management: Beginner’s Guide, and Agile Methodology for Lawyers: Beginner’s Guide.

The Lean Methodology

The Toyota Production System, or TPS, which transformed the production of tangible items in the 1950s, 1960s, and beyond, is where the lean methodology developed. Lean continues to be influential in manufacturing, but it has also developed innovative solutions in knowledge creation that benefit organisations across all sectors by reducing waste, streamlining procedures, and fostering creativity. The Lean technique is built around two main principles. Without accepting both, a company cannot practice lean:

- Continuous Improvement

- Respect for People

Continuous Improvement

Continuous improvement is essential for a methodical, coherent, and result-yielding process.

This can be achieved through the PDSA (Plan, Do, Study, Act) and DMAIC (Define, Measure, Analyze, Improve, Control) cycles.

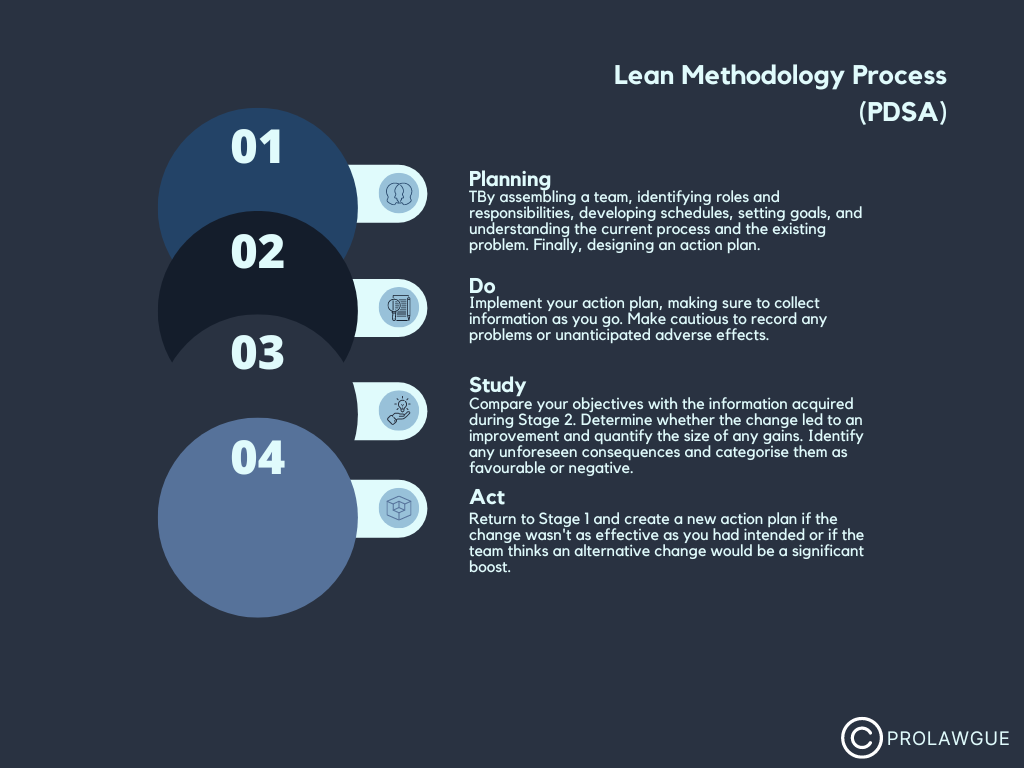

PDSA involves:

- Planning: By assembling a team, identifying roles and responsibilities, developing schedules, setting goals, and understanding the current process and the existing problem. Finally, designing an action plan.

- Do: Implement your action plan, making sure to collect information as you go. Make cautious to record any problems or unanticipated adverse effects.

- Study: Compare your objectives with the information acquired during Stage 2. Determine whether the change led to an improvement and quantify the size of any gains. Identify any unforeseen consequences and categorise them as favourable or negative.

- Act: Return to Stage 1 and create a new action plan if the change wasn’t as effective as you had intended or if the team thinks an alternative change would be a significant boost. If the modification was found to be successful, standardise the enhancement. After some time has passed, you can go back to Stage 1 and look into the procedure to see how it might be improved.

DMAIC (Define, Measure, Analyse, Improve, Control)

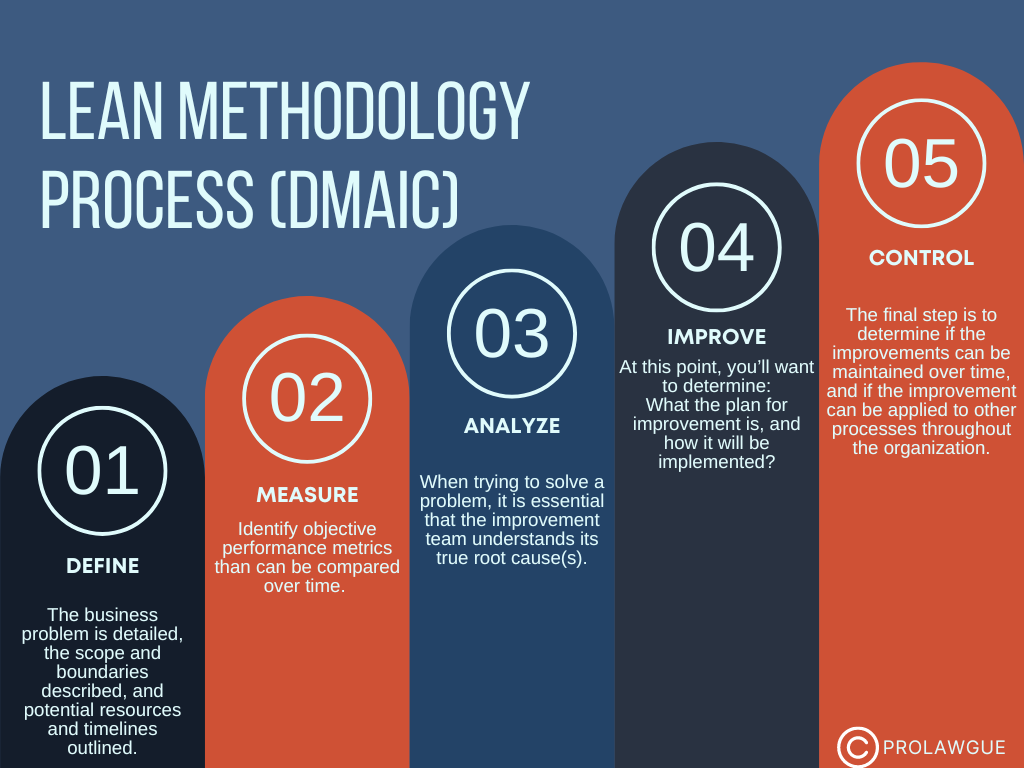

The Six Sigma framework tool DMAIC (pronounced “de-may-ick”) describes a strategy of locating and confronting sources of waste, subpar quality, and inefficient operations in search of possibilities for improvement.

Find more information about DMIC here.

Respect for People

The best ideas frequently originate from those who are directly in charge of creating the good or rendering the service, according to lean thinkers. So they oppose top-down management and give equal voice to those who are nearest to the industry or the client. Giving employees the resources and instruction they require for success is a vital method lean firms deploy to show respect for their workforce. Lean leaders take the time to make sure that everyone is familiar with the methods the company will employ to implement, oversee, and track improvement activities. They also spend money on software, training, and other resources needed to achieve operational efficiencies.

5 Fundamental Principles of Lean Methodology

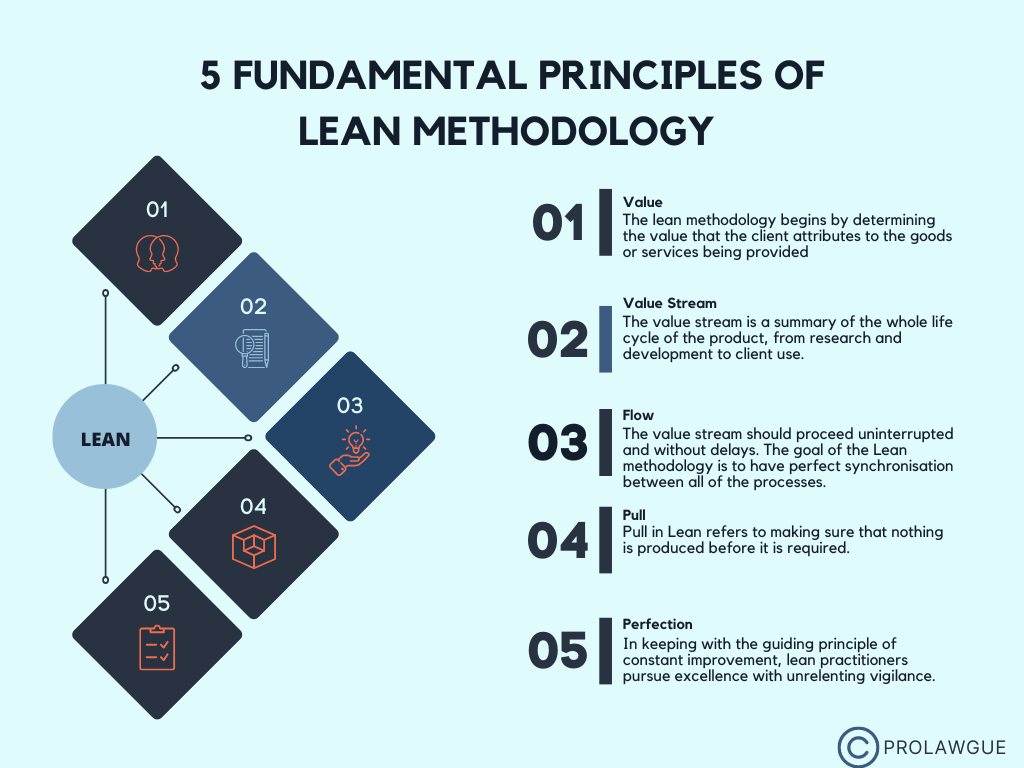

- Value

The lean methodology begins by determining the value that the client attributes to the goods or services being provided. All value is determined by the buyer, not the producer. The price is set depending on the customer’s ability to pay, which establishes the product’s maximum permissible cost. The company then concentrates on reducing waste in order to satisfy the consumer while maintaining maximum margins.

- Value Stream

The value stream is a summary of the whole life cycle of the product, from research and development to client use. In order to maximise value and avoid waste, a comprehensive evaluation of the value chain is required. Each procedure is evaluated to determine the value it adds. Materials, features, and processes that don’t increase value are eliminated.

- Flow

The value stream should proceed uninterrupted and without delays. The goal of the Lean methodology is to have perfect synchronisation between all of the processes. One of the prerequisites for just-in-time production is a fluid process flow.

- Pull

The concept of pull is what enables flow. Pull in Lean refers to making sure that nothing is produced before it is required. In a lean organisation, no work is produced prior to an internal or external customer placing an order, as opposed to relying on a prediction and schedule. This provides flexibility and enables quicker delivery cycle times. Of course, it calls for a reliable method of conveying what is required at each stage of the value chain. Widely employed is the Lean approach known as Kanban, which conveys process flow using visual indicators.

- Perfection

In keeping with the guiding principle of constant improvement, lean practitioners pursue excellence with unrelenting vigilance. Compared to their less successful competitors, they delve deeper into the underlying causes of quality issues and waste, use more exact measures, and effectively implement small improvements.

Read more about the kanban principle here.

Lean in Law

Lean fundamentally entails examining your processes for doing legal work and categorising each assignment into one of two groups:

- Things that benefit the client or customer.

- Things that don’t contribute value are referred to as waste in the lean system.

Lean aims to eliminate waste so that it may concentrate on procedures that provide value.

Around 2005, pressure on law departments in large organisations increased, and attention was focused increasingly on how much money was being spent on legal matters. Counseling was once considered to be a fixed expense. Companies then began to consider budget management more carefully. This has forced legal departments to work harder for less money. Despite an increase in legal needs, law departments’ resources are declining.

A GC and their team should adopt the attitude of a Lean Legal Function for three main reasons.

- The first thing GCs will discover is that there are ways to reallocate capacity from low-value jobs to higher-value ones by reducing workloads in those regions.

- Second, a GC can promote demonstrable continuous improvement over time by utilising the Lean method.

- Thirdly, GCs can utilise Lean terminology to defend present resources and request more resources in order to increase ROI for important stakeholders.

The agile approach, a branch of software development, saw the first Lean methodology used outside of manufacturing. Agile software development, which aims to optimise the software development cycle, is conceptually similar to Lean development.

Seyfarth Lean

Seyfarth Shaw LLP was the pioneer law firm in implementing the Lean Methodolgy in law. They have curated a unique service model called ‘Seyfarth Lean’, which combines client feedback (called ‘voice of the client’), standardised trial process maps and alternative price agreements.

Lean Six Sigma Techniques

Lean management and the enormously well-liked Six Sigma are additional developments of lean manufacturing.

Lean Six Sigma’s fundamental tenets are:

- Put the customer first: In order to run a client-centered legal practise, you must put your clients first in all of your decisions. Beyond the legal deliverable you present, this also includes: considering the process of choosing a lawyer and dealing through a legal problem from your client’s perspective. It also entails considering how you may deliver a positive client experience in a way that is effective for your company.To be able to center your law firm around clients, it is important to be mindful of the client journey, and enhance customer experience. A helpful tool in this regard is the NPS metric (Net Promoter Score)

- Determine and comprehend the process of doing the work: This can be done through Legal Process Mapping. Legal process mapping can be defined as a graphic representation of each stage, touchpoint, task, individual, and resource used to produce a typical legal output. An effective map should demonstrate what lawyers do, how they do it, how they connect with other staff members (paralegals, administrative), and how the above-mentioned processes flow.

- Legal Process Improvement: Control, enhance, and streamline the process flow.Eliminate waste and steps that add no value, Reduce variation and manage by facts, Equip and include the people in the process, Conduct systematic improvement activities.

To better understand these techniques, you can read our Project Management Guide: A Beginner’s Guide and The LPM Guide of Cliiford Chance.

Project Management Guide

Resources:

Articles and Guides:

- Applying Continuous Improvement to high-end legal services – Clifford Chance January 2014

- An Introduction to Lean Six Sigma As Applied to Law Firms – Lisa Gianakos, Legal Solutions, Thomson Reuters October 2014

- Lean for Law: Legal Process Improvement Checklist – Karen Dunn Skinner, Gimbal Canada Inc. with Practical Law Litigation

- Lean, Kanban, and how they work together – Leankit

- Lean Legal: Three Techniques for Agile Lawyer

- Getting started with Kanban

- What is Lean Law? A Conversation with Expert Kenneth A. Grady

Books

- Lean Six Sigma for Law Firms Reviews & Ratings – Amazon.in

- The Lean Law Firm

- Lean Six Sigma- Michael L George

- The Lean Six Sigma: Guide to Doing More with Less

Training and Courses

- Build a Better Law Practice- Gimbal Canada

- Six Sigma Training

- Lean Six Sigma Courses

- Legal Lean Sigma Institute Courses and Certifications